Starting a children’s clothing brand? Did you know, children’s clothing brands are faced with more rigorous quality requirements than adult clothing brands? This is why we created the 7 key factors to consider when selecting a children’s clothing manufacturer.

As a children’s wear brand owner, you’ll want to make sure you offer seasonal styles. But it’s important to also ensure your garments are comfortable, and safe, for the kids who wear them.

It’s time to look beyond just the cost of manufacturing children’s clothing. Instead, let’s look at other important factors when you’re searching for the best children’s clothing manufacturer.

1. Best Fabrics For Children’s Clothes

Your customers are the kids who wear the clothes you sell; not the parents who buy them. If a child doesn’t like how your clothes feel, they’ll tell their parents not to buy from your brand again.

Understanding the impact your factory’s fabrics have on children’s skin is critical to the success of your sales.

When it comes to choosing fabrics for your children’s wear, it’s important to consider skin health and comfort of movement.

Curating a wardrobe that’s adaptable, functional, and comfortable for the little ones needs to be your first priority.

Does your kids wear manufacturer have the best certified fabrics in the following categories?

Natural Fabrics: Organic Cotton, Euro-Flax Linen, Lenzing Tencel™:

Natural fabrics such as organic cotton, Euro Flax certified linen, and certified Tencel™ made by Lenzing are generally the best options for children’s clothing; especially babywear.

They’re gentle for children with allergies or skin irritations. These fabrics are also great for active children who need comfortable, stretchy clothes that move with them.

Check out CM Garmindo’s top rated Knit fabrics and Woven fabrics.

Synthetic Fabrics: Polyester & Nylon:

Fabrics such as Polyester and Nylon are often used in children’s swimwear but can also be used for resort wear like girl’s dresses.

If you’re manufacturing children’s swimwear, then you’ll want to consider recycled swimwear fabrics because they’ll also be UPF50+ protective.

Check out CM Garmindo’s recycled swimwear fabrics.

Breathability & Durability:

Breathable fabrics should be considered when manufacturing clothes for active kids because they improve ventilation, prevent overheating, and reduce moisture build up.

Durable fabrics are important for children who play rough, as they can better withstand wear and tear. Think overalls made of a strong Cotton Twill.

In both cases, ask your children’s clothing manufacturer about the yarn density and gsm weight of their fabrics. A high yarn density with a light yarn means the fabric will be soft and smooth but not heavy.

2. Manufacturing Proper Fitting Clothes

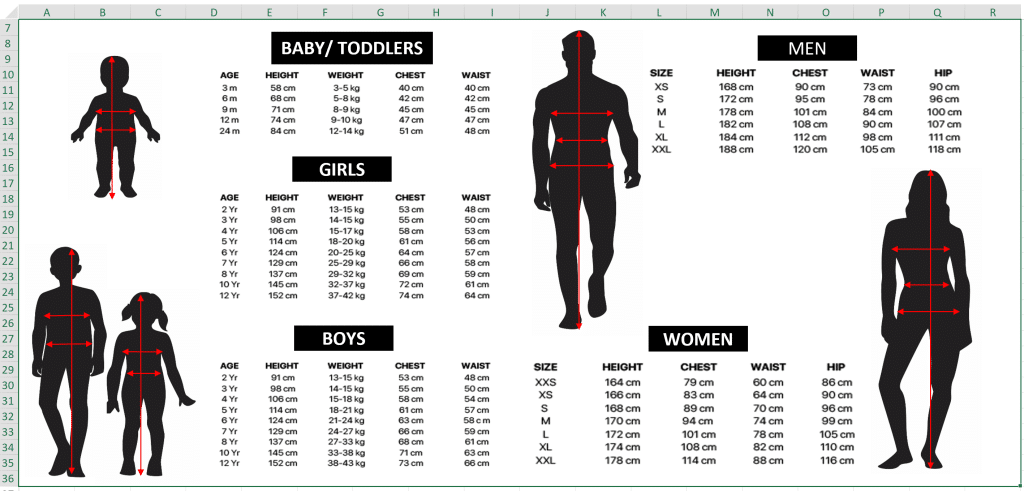

Whether you see it in their Private Label catalogues or whether it’s part of their custom design process, your children’s clothing manufacturer should have the perfect fitting size charts ready for you.

But if you’re designing your own clothes, the alternative way to get the perfect fitting clothing is to download a size chart from any major brand. They’ve already done the research for you!

Proper fitting clothing looks good but is also a matter of safety. For example, if the sleeves or feet on a sleepsuit are too long, the child might trip while trying to walk or get caught on the corner of furniture and fall.

If you’re selling babywear, consider using natural fabrics that have a little bit of Spandex in them for that slight stretch. Perhaps use CM Garmindo’s 96% Tencel / 4% Spandex.

3. The Importance of Proper Sizing

Just like proper fitting clothes, proper sizing is another critical factor when considering how you manufacture your clothes.

Children grow quickly. A child’s mobility varies at different stages of development.

You want your customers to keep buying from your brand. This is why it’s essential to work with a factory that knows how to make all of your sizes fit properly across all age and size ranges.

In our industry, we call this “size grading” or “pattern grading”. It’s when we take your master sample in one size, and make all the other sizes fit properly too.

Does your garment factory have a robust grading process?

4. Balancing Style & Functionality: What Sells?

At CM Garmindo, we understand that you’re a business. We know you need to generate consistent revenue.

But you need to stop chasing trends. By the time you hear about a trend, it’s already too late anyway.

The best thing to do when you’re considering which garments to manufacture for your collection is to balance the styles against their functionality.

Cool styles sell seasonally but functionality always sells. This is why we offer private label manufacturing where you can customise timeless classics we’ve predesigned.

Think about it from your customers’ perspective. They want clothing that looks good but they also want clothes that last.

You’ll want to manufacture clothes that are easy to wear, that can last through numerous washes, that parents love seeing their kids in, but that kids can also use over again.

Also, try to design your collections to include multifunctional wardrobe essentials, such as playsuits or rompers that can be dressed up or down.

5. Experience & Ethics Over Cost

We understand that you’re going to consider manufacturing costs but experience and ethics trumps cost, every time.

Firstly, low cost often means unethical and low quality. This is one of the reasons why our industry is loved and hated at the same time. Cheap, at the cost of hurting people.

One of the crucial key factors to consider when selecting a children’s clothing manufacturer is ethics. Is your garment factory ethical Fair Trade?

If not; it means they don’t care about people or the environment. As a brand that serves children, why would you even work them?

Apparel manufacturers that focus on ethics also focus on quality; it’s in our nature. And with focus on quality comes experience.

As a leading ethical Fair Trade children’s clothing manufacturer, CM Garmindo is known as a specialist in kids wear.

This means we employ highly skilled workers. We use top of the line modern machinery. And we source the best fabrics and materials from around the world.

Being ethical also means we adhere to internationally recognised quality, safety, and environmental standards such as ISO 9001 and ISO 14001. Does your factory work within these frameworks?

6. Clothing That’s Certified For Quality and Safety

Did you know? Any children’s clothing that’s manufactured overseas and shipped into the USA has to be compliant with the Consumer Product Safety Improvement Act (CPSIA).

Other regions also have their own quality and safety standards for children’s wear such as REACH for the EU, CCPSA for Canada, SASO for Saudi Arabia, amongst others.

As the brand owner, it’s your responsibility to know which regulations your garments need to comply with. But your manufacturer should at least provide the testing service to you.

CM Garmindo works with the world’s largest garment testing auditor called Intertek. We test clothing and textiles for chemicals and bleaches, flammability, mechanical hazards, seam and tensile strength, and more.

If your children’s clothing manufacturer doesn’t test for these regulations, you could be endangering your customers, and your brand.

7. Reputation & Reliability

Getting references from your garment factory is important to build trust. But you’re not guaranteed that the references will talk with you. For example, our clients rarely speak to 3rd parties for privacy reasons.

Another great way to check references is to read online reviews about your prospective kids clothing manufacturers.

We recommend looking for a manufacturer’s Google Reviews. Check out our amazing clients’ reviews of CM Garmindo here.

Ready To Manufacture Children’s Clothing?

Starting a children’s wear business is challenging. It’s a highly competitive market. That’s why it’s important to take the time to research prospective manufacturing partners.

Having said that, our 7 key factors to consider when selecting a children’s clothing manufacturer should equip you to get started with ease.

We’d love to hear your feelings. What’s your experience sourcing clothing manufacturers for your children’s wear brand?

If you have any questions or need more tips for working with children’s clothing manufacturers, drop us a message on our website here.