Our clients regularly ask us what the difference is between cut sew activewear versus circular knit activewear. This might sound obvious because of the terminology, but it seems to stump many brand owners.

What we’re talking about is two different types of manufacturing.

Pro tip: you can easily tell by looking at famous activewear brands such as GymShark.

Before we proceed. It’ll make your life easier if we simply define what “cut sew clothing manufacturing” and “circular knit clothing manufacturing” are.

Cut Sew Activewear Manufacturing:

This is exactly what it sounds like. We cut fabrics into panels, and then we sew them together.

Cut sew manufacturing is how most clothes are made. Even home sewers are doing cut sew productions.

Here’s a short video showing a perfect example of what cut sew clothing manufacturing looks like: https://www.instagram.com/p/C8g1RT0uyWq.

As you can see, one of our cutters is using a machine to cut the fabric into the different shaped panels. And then you see the panels being sewn together to make the clothing.

Here’s an example of one of our cut sew activewear garments:

Circular Knit Activewear Manufacturing:

This requires large yarn-knitting machines. These machines look similar to the machines we use for making socks – but a bit different.

You can see an example of what our sock making machines look like in this video, which is similar: https://www.instagram.com/p/ByEb6wzlyuI.

Circular knit garments are essentially knitwear. Just like how you would knit a cardigan.

As mentioned in the introduction, GymShark is a famous activewear brand that’s known for circular knit activewear.

Here’s a video directly from GymShark’s own factory where they make seamless activewear. Skip to timestamp 7:12: https://www.youtube.com/watch?v=jaSteuqkn8E.

Benefits of Cut Sew Activewear Versus Circular Knit Activewear

Now that you know the difference between cut sew activewear versus circular knit activewear, let’s explore the benefits and drawbacks.

Cut Sew:

- Cut sew activewear is easier to make. Anyone with scissors, a proper sewing machine, and some skills can make this type of activewear.

- Because this type of garment making is so ubiquitous, it also costs less. Depending on the complexity and the fabrics, of course.

- With so many manufacturers capable of making cut sew activewear, you can find low MOQ clothing manufacturers like CM Garmindo.

- To have any surface designs, cut sew activewear needs to be embroidered or printed which needs the correct machines. This increases your costs.

Circular Knit:

- Circular knit activewear is not possible for the average person to make. You’ll need to make this at a properly equipped factory.

- Because making circular knit activewear can be made at only a few large industrial factories, manufacturers can demand larger quantities.

- Since there are few factories who can make circular knit activewear, they tend to have a monopoly on the sector and can charge more.

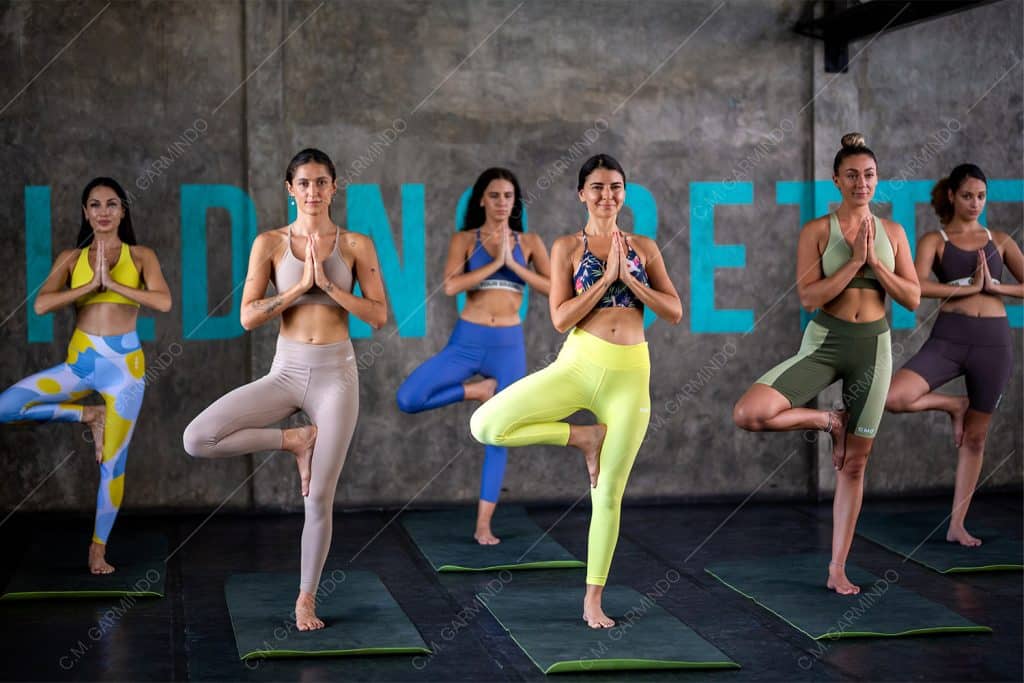

- With circular knit activewear, you can knit design motifs directly into the garment. This means circular knit activewear doesn’t need to be embroidered or printed. The designs are created into the fabric as the garment is knit.

Check out this example of one of GymShark’s seamless activewear tops:

Conclusion

Learning the difference between cut sew activewear versus circular knit activewear, will make it easier for you to know which type of apparel manufacturer you need to research.

- Circular knit activewear, or seamless activewear, is really cool. You can get super soft, high-performance activewear, with unique designs.

- But it costs more because there’s only a few manufacturers in the world who can make them.

- Cut sew activewear is everywhere, and it costs less to make. Usually.

- But if you want your own unique designs, you’ll need to pay more to embroider or print them.

Regardless which option you choose for your own activewear brand, there are vast opportunities for growth in the activewear market. Health-conscious consumers are everywhere.

If you’re looking for circular knit activewear factories, search Google using phrases like “circular knit activewear manufacturer” or “seamless activewear manufacturer“.

And if you add the name of a specific country, you’ll get better results.

If you’re looking to start your own cut sew activewear line, CM Garmindo can help. We’re Bali’s No. 1 activewear, gym wear, and yoga wear manufacturer.

Contact us today; we’d be happy to answer all your questions.